Services

- Home

- Services

Services

The GRANTE Zrt. team is always happy to listen to the customer's wishes. Even the slightest special request is met, because we know that progress never stops.

Development

Modelling and simulation

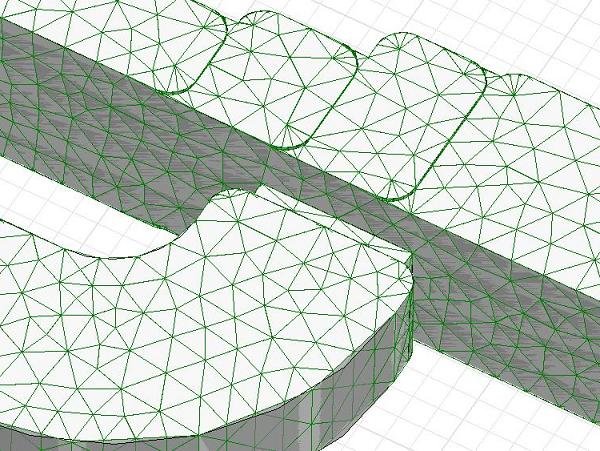

The high quality of our products is guaranteed by the state-of-the-art modelling and simulation procedures used in their design.

Ongoing consultation with our partners is also vital for us.

We believe that our flexibility and uniquely short response times help all our partners to find the best solution for any situation.

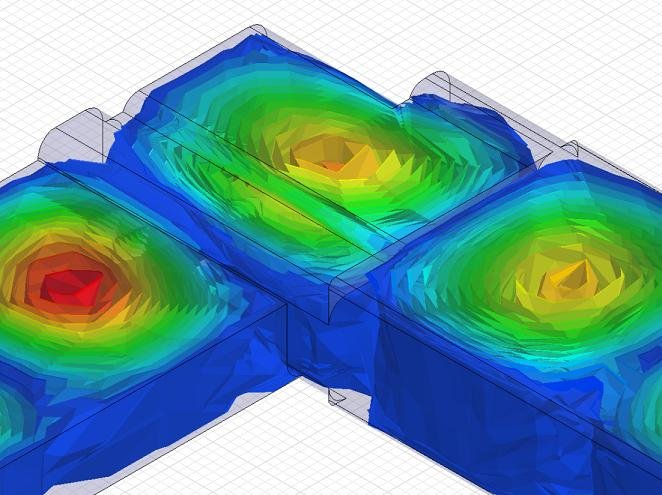

3D model of the elbow and the distribution of the electric field strength in the pipe

The values of the electrical parameters of our products calculated in simulations are a good approximation of the results of subsequent measurements

The values of the electrical parameters of our products calculated in simulations are a good approximation of the results of subsequent measurements

Microwave measurements

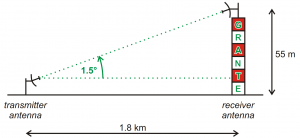

Antenna radiation characteristics are measured on our 1.8 km long measurement section, chosen to minimise ground reflections.

Primary radiation is measured in an anechoic chamber or in a parabolic reflector covered with a special absorbing material.

We have high-precision measuring instruments up to 90 GHz.

Lined parabolic mirror with handle

Anechoic chamber

Technology

All GRANTE products are developed, designed and – with the exception of a few special surface treatments – manufactured in-house.

Our antennas are made from aluminium using our own patented technology. In addition, we mount our antennas with different radomes (conical, rigid-flat, flexible/flexible-flat) to meet different needs. The antenna support structures are made of hot-dip galvanised, stainless steel and aluminium elements.

High-precision feed line sections are machined by CNC machines.

HPA antennas with a diameter of 0.8 m or more are equipped with side supports to ensure the necessary stability

0,6 m diameter HPA antenna with flexible/flexible-flat radome

Tubular coupling during CNC machinin

Environmental conditions

Our antennas are generally rated for 120 km/h operating winds and 220 km/h survival winds. The survivability value can be increased to 240 km/h with optional accessories.

The operating temperature range is -55°C to +55°C with a maximum relative humidity of 100%.

Using a flexible/flexible radome reduces the chance of ice build-up

Timeless design

Today’s expectations for microwave networks place huge demands on service providers. High availability and capacity are essential, but implementation is not trivial. End-users demand continuous bandwidth growth and reliable operation, but environmental conditions place a strong constraint on the number of antennas that can be deployed.

We offer a time-proven modular solution that allows for flexible and scalable upgrades of microwave sections. A unique solution for those who are already looking at the networks of the future.

Packaging

Currently the only polarisation using a redundant (1+1) system. Using the second polarization -- 2x(1+1) arrangement -- the transmission capacity can be doubled.

When packaging our antennas, we aim to minimise the effort our customers have to put in during installation. To achieve this, we ship almost everything assembled, so the final assembly of a 1.8 m diameter antenna takes no more than a few minutes.

We also try to meet our partners’ specific packaging requirements in every case.

1.8 m diameter pre-mounted antenna in steel frame. Final assembly takes 15...20 minutes

Product Design and Prototyping

Let’s evolve together! Development and manufacturing in one place.

Countless good and marketable ideas remain unrealised because product design, possibly grants, finding investors, preparing prototyping and series production, preparing documentation, etc., is too much of a task for individual entrepreneurs and start-ups.

With the help of our engineers, specialists and network of contacts, we are happy to work with any company that contacts us.

Thanks to our flexibility and our efficient development and innovation capabilities, we develop on average 60-70 new tools (so far typically in-house) every year. For 25 years, our specialists have been developing our products in line with the needs of the market, which has enabled us to produce a large number of tools that meet specific requirements and are used successfully by our customers. Problems and new issues that arise during the design and manufacturing process can be dealt with quickly and efficiently. We have the infrastructure and machinery to produce a wide range of products and, with the help of our partners, we can coordinate the production of tools that we cannot manufacture ourselves.